Next-generation revolution in technical publications

Next-generation revolution in technical publications delivers higher-quality, faster, more economical maintenance

In the realm of engine technical publications, Cortona3D has been selected to revolutionize the way one leading U.S. manufacturer of aircraft engines and components accesses and manages its fleet technical data.

This manufacturer has achieved an industry first by leveraging CAD assets for their interactive 3D content across all customer support information, including:

- Illustrated Parts Catalog

- Illustrated Tool and Equipment Manual

- Systems Description Section

- Engine Manual

- Cleaning, Inspection, and Repair Manual

- Computer-based training modules

Speeding the Authoring Process

The impact of deploying Cortona3D software to produce its fully digital technical publications is a cost savings of 87%.

Immediately, we cut authoring from eight hours per page down to one hour. Now we’re even faster because we’re more familiar with the tool.

"Cortona 3D gives us a unified authoring space where we import UGS Teamcenter or other CAD graphic sources and Microsoft Excel parts lists. We give parts and assemblies interactive 3D capabilities and can crosslink any item to any other item. We enable users to filter by model, service bulletins, and user codes to enhance search and ease of use. The tool also supplies digital output in SGML, HTML, and XML."

"We used to manually import, edit, redraw and page-reference many iterations of engineering drawings, parts lists, and instructions from many sources. This formerly took two writers and a number of illustrators two years to complete. What we once redrew and redescribed, we now import and link. So the 3D IPC is a far superior tool, and it only took nine months with one author and one illustrator to produce. The result is a substantial cost saving."

Efficient and effective

Cortona3D allows all of the resources to be centrally managed so that future updates and revisions can be more easily and efficiently generated. Also, the accuracy and quality of data are greatly improved by leveraging up-to-the-minute CAD data from engineering and design. Finally, given a huge distribution network, it is a massive advantage to this manufacturer to be able to make deliverables available with real-time updates online.

We wanted to ensure that our technical publications' products keep pace with our engine technology, providing our customers with cutting-edge products that add value to their airline operations.

Interactive and intuitive

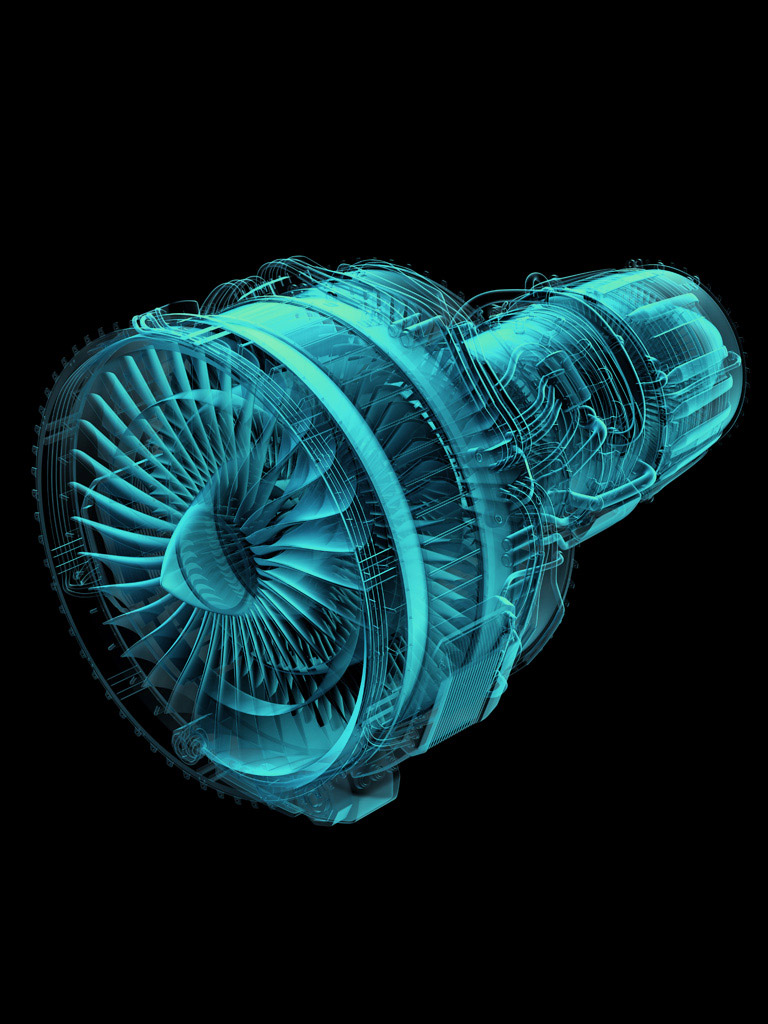

Users of the 3D deliverables can enjoy a new and interactive experience—where they can zoom, rotate and explode on-screen views of assemblies and subassemblies with identifiable part names and numbers. They can hide parts or make them transparent, and trace the paths of tubes and harnesses. Parts names and numbers are displayed on the same page.

“Integrating the 3D IPC’s interactive illustrations with identifiable part names and numbers gives our customers a solution that is more intuitive and much easier to use. The IPC also enables users to generate a purchasing list for ease of parts ordering. Its 3D graphics can be leveraged to various documents and used as training tools.”

The new 3D IPC is a step improvement over traditional manuals. It has the multiple benefits of being able to identify the parts you are looking for much more quickly, visualize the assembly of parts, and demonstrate the relationship a part has to adjacent parts. It is particularly impressive when using the rotation feature to follow external tubes and harness runs around the engine, making it much easier to interpret than traditional manuals. It will offer productivity improvements to mechanics and staff.

Upgrading to next-generation fully digital 3D technical publications was made possible using Cortona3D from ParallelGraphics. Further competitive advantage may be gained in using Cortona3D authoring tools to pull and cross-reference graphic digital engineering data through other customer documentation including service bulletins, engine manuals, and computer-based training materials.

Next-generation technical publications allow users to:

- Create a “pick list” to easily generate parts requests

- Create training tools by leveraging the 3D graphics to other documents

A major United States manufacturer of aircraft engines and components whose new technologies merit advanced parts and maintenance procedures documentation.

- RapidCatalog

- CAD materials were not being leveraged as optimally as engineers and users envisioned was possible

- The latest generation in aircraft engines required the best possible documentation

Cortona3D documentation software and techniques were chosen as the best technology for this application to automate and distribute ever-changing documentation.

- 87 percent cost savings

- Authoring time drops from eight hours per page to one hour

- Changes can be instantly disseminated worldwide in a variety of formats

- Users manipulate images on-screen for greater clarity and ease of learning